GROWING STRENGTH TO STRENGTH EVOLVING IN CLASS, CONSISTENTLY

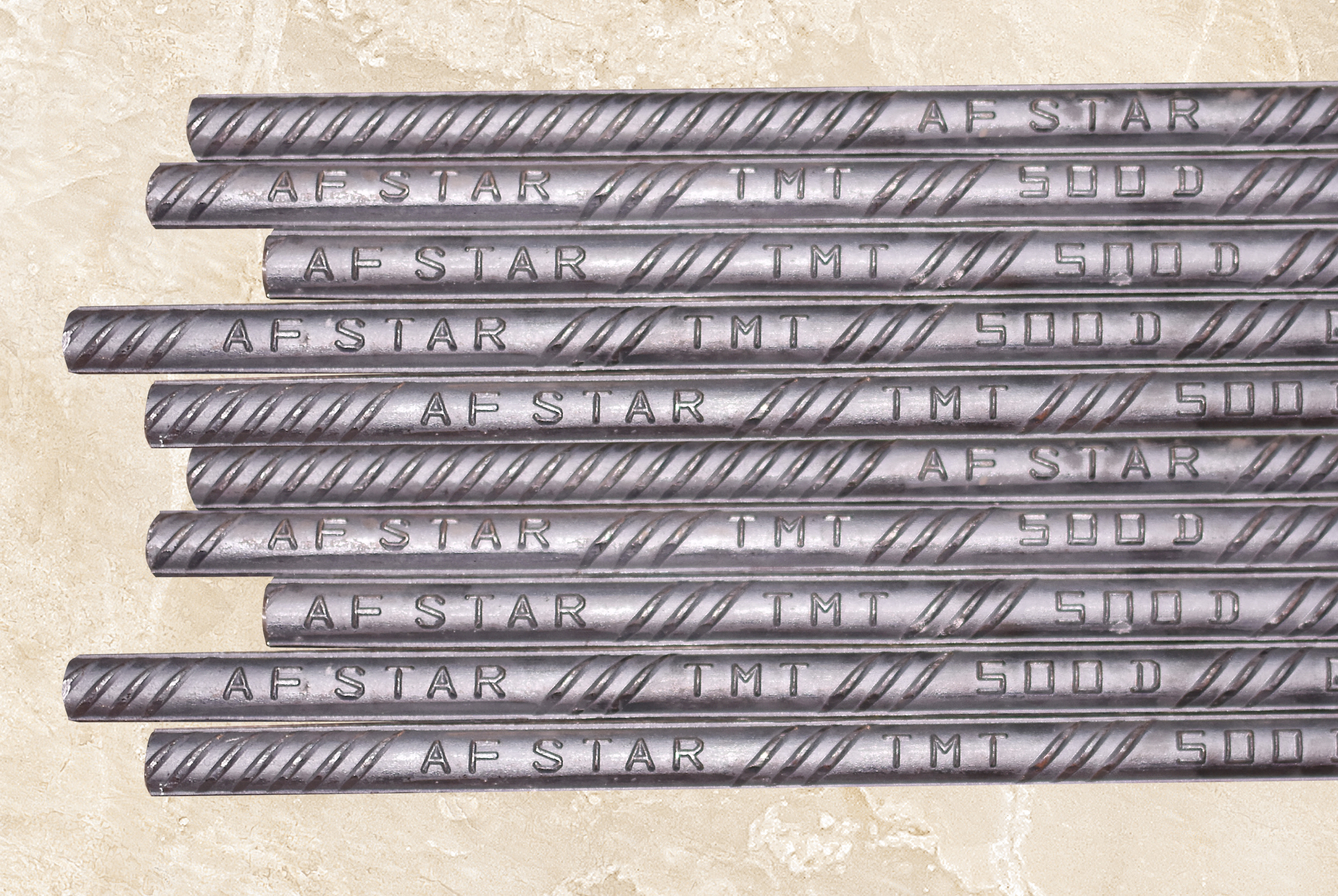

Through flagship brand AF Star, we own a complete range of product variants that include TMT bars in various categories, cut and bend, and round bars. Our broad range features superior standards and meeting distinct industry needs. MSAF products surpass the test of the time and demands of the discerning clientele, especially massive and complex projects, such as bridges, metro rails, irrigation and power, and modern industrial and residential construction.

Our products carry the unique stamp of distinct characteristic features – tough and malleable. Their range of elongation ratio varies from 18% to 24% which makes them highly ductile and easily weldable. The Thermo Process German technologies like stop-start shears and patended Thermex treatment systems undertaken by AF Star, has helped produce high-end strong deformed steel at economical costs. It has made the Company one of the biggest suppliers of steel for civil construction purposes in India. Not to forget the fact that the stringent quality stands have ensured the quality of the products is top-notch earning them the license to produce and sell bars in the entire sub-continent.

All our products are manufactured under superlative technological powering, metallurgical process using electric arc furnace. Besides boasting of impeccable tensile strength, durability, and quake resistance, they are developed as cost-effective steel with corrosion resistance products.

Fe 550D TMT Bars

High-strength reinforcement bars that are used in various construction projects requiring durability of structures. A popular choice among builders and engineers, used in a variety of applications, especially fitting the needs of high-rise and long-span structures

Benefits and Features

-

Boast of superior grades and uniformity in properties featuring high-tensile strength, excellent ductility, corrosion resistance, fire resistance, and quake resistance

-

Reduced steel consumption by 12-15% with optimization, using consistent primary steel.

-

Minimizing bar congestion by use of strong-grade steel

-

Reduced labour cost through use of lesser steel

-

Accelerated construction, less time consumed in placing/ tying of rebars and less weight on cranes, improving construction efficiency.

-

More savings, thanks to stronger bars that bring down overall steel consumption and an increase in Floor Space Index, where extra space generated can be monetized

-

Cost-effective and increasing profitability, due to less maintenance and need for repairs

Fe 500D Corrosion Resistant Steel TMT Rebars

Fe 500D Corrosion Resistant Steel TMT symbolize the blend of strength and longevity, offering structures extra and special coating to prevent rusting The coating comes from materials such as zinc and polymer used protective layers that protects steel from being exposed to moisture and other corrosive materials. Our Fe 500D Corrosion Resistant Steel TMT is considered to be among the TMT strongest grade available that can withstand quakes, nature’s extremes in coastal and high humidity regions

Benefits and Features

-

Known for higher strength, made with advanced technology, and ideal for use in construction projects that require high load-bearing capacity.

-

Conforming to superior standards, taking care of safety and structural integrity of constructions

-

Promising improved chemical resistance due to superior resistance against environmental factors, including saltwater, harsh chemicals, and other potentially damaging elements.

-

Highest degree of weldability, making them ideal for application in complex construction projects with customized designs.

-

Cost-effective compared to other types of construction materials

-

Uniformity ensuring each bar has uniform dimensions and properties.

-

Eco-Friendly process of manufacturing, minimizing wastes and reducing environmental impacts

AF Star Fe 550D Epoxy Coated TMT Rebars

Popular choice highly sought after for corrosion resistance, and enhanced durability. The epoxy coating acts as a protective barrier preventing damage from moisture and other corrosion agents. Extensively used by buildings of all categories, bridges, marine structures, quake-resistant structures, and rehabilitation structures.

Benefits and Features

-

Superior corrosion resistance, providing flawless protection against corrosion caused by moisture, chemicals, and environmental factors

-

Extending lifespan of structures significantly, reducing maintenance costs over time.

-

Enhanced bonding strength through ensuring excellent adhesion between the rebar and concrete, resulting in superior bonding strength

-

Improving the structural integrity and load-bearing capacity of reinforced concrete structures.

-

Always extending high tensile strength, fire resistance and quake resistance Cost Savings by bringing down corrosion-related damage risks

-

Always promoting optimal structural stability, suitable for several construction applications

-

Highest degree of safety through fire-resistant properties of the epoxy coating

Mild Steel Rounds

AF Star Mild Steel Round Bars are practically used in every industrial and construction application, thanks to the strength and durability, made of steel that contains carbon levels as low as 0.25%. This automatically translates into more ductility and being malleable than the peers in the market. Well-suited for, and trusted by road builders, forging industries, bright bard industries, auto-ancillaries, chemical, agro, and engineering industries

Benefits and Features

-

Enviable sizes range, available between 8MM and 32MM

-

Superior grade E: 250 steel as raw material known for strength, structural integrity, and affordability

-

Customizable dimensions where the bars come in different lengths, widths, and dimensions fitting precisely for applications

-

Broad application range used for diverse industries, from construction to chemicals, engineering to auto

-

Compliance with stringent standards specified in IS 432-part-1, assuring customers of the reliability and consistency of the product

-

Superior ductility using mild steel that has a lower carbon content than other types of steel

-

Unfailing in corrosion resistance, making it ideal for use in outdoor applications

-

Mild steel can be easily machined, making it an ideal choice for production of tools and appliances

-

Highly recyclable, making it an eco-friendly choice for construction and manufacturing projects.

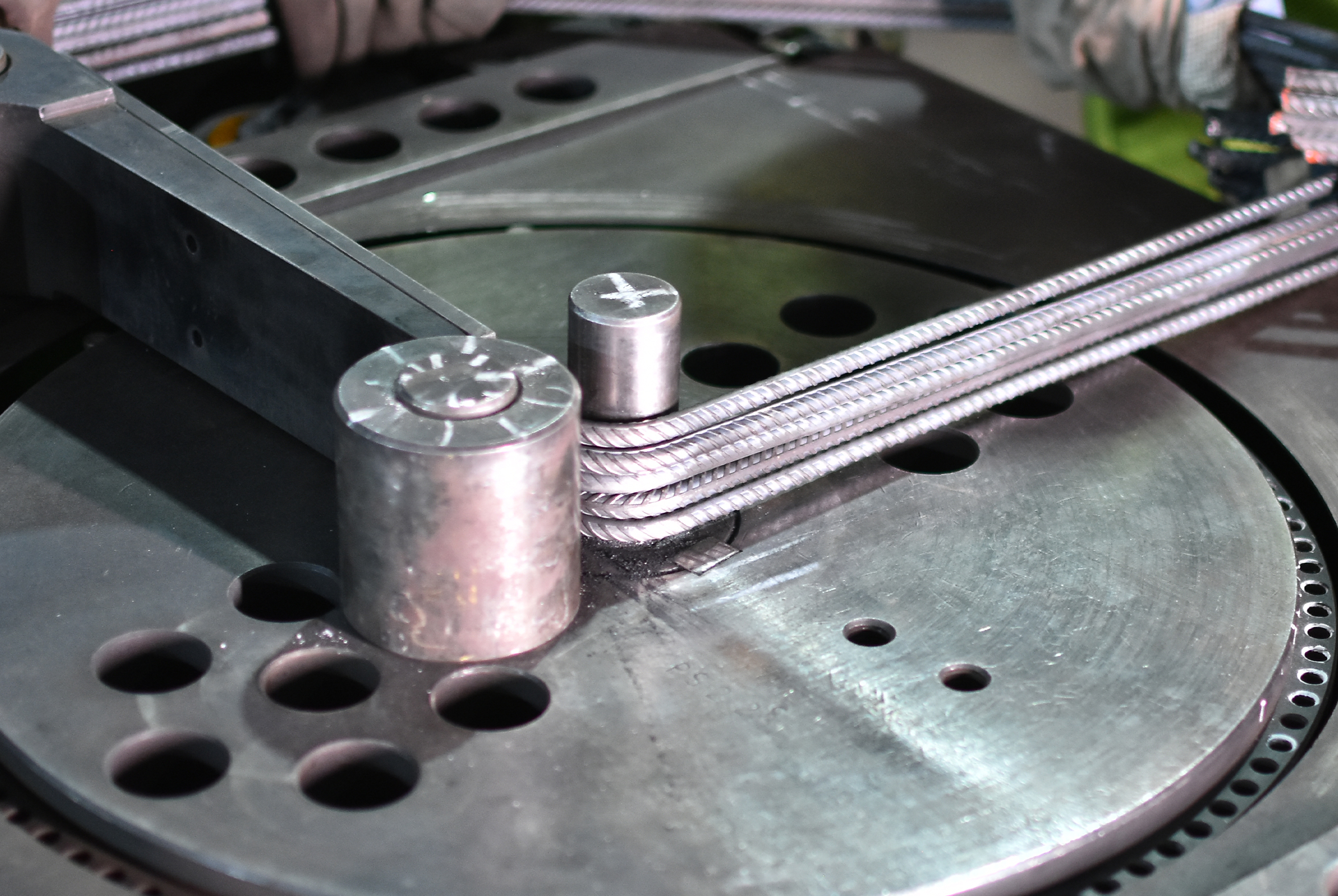

AF Star Cut and Bend

Cut and Bend steel is a prefabricated steel reinforcement material used in construction projects. It is produced by cutting and bending steel bars according to specific sizes and shapes as required by the project specifications

AF Star is a pioneering brand in the steel industry and is one of the first steel industries in the country to introduce Cut and Bend TMT bars for the first time. This innovation has revolutionized the way steel features and performs

Benefits and Features

-

High-quality manufacturing using advanced technology and a controlled process that ensures high quality and consistent mechanical properties

-

Made from high-strength steel and undergo a thermo-mechanical treatment to enhance their strength and durability

-

Customized shapes and sizes of TMT bars ensuring seamless integration into the structure, minimizing time and material wastage

-

Precision in cutting and bending to the degree of bend and accuracy up to +/- 1 mm, thereby eliminating the need for on-site cutting and bending, saving time and money

-

Corrosion resistance, with AF Star Cut and Bend TMT bars typically coated with anti-corrosive materials

-

High strength and ductility, withstanding heavy loads and structural stresses, and standing the test of ductility that prevents them from getting deformed due to excessive loads

.

-

Cost effective and time saving as it increases the scope of using pre-cut and pre-bent TMT bars

-

More structural integrity and design flexibility, simplifying complex structural needs, and manufactured to precise dimensions, ensuring accurate reinforcement placement within the concrete structure